Bangladesh’s Ready-Made Garment (RMG) industry operates in an environment of tight contribution margins, increasing compliance costs, and rising minimum wages. While fabric and trims are largely buyer-driven costs, labour cost remains the most controllable expense for factory owners.

Among all labour-related levers, Man-to-Machine Ratio (MMR) and CMV (Cost per Minute Value) efficiency stand out as the most powerful and measurable tools to optimise costs and maximise profit without compromising compliance or quality.

Labour cost typically represents 25%–35% of total conversion cost in Bangladeshi garment factories. Many factories still rely on overtime, excess manpower, or informal buffers to meet shipment deadlines—resulting in hidden inefficiencies and inflated CMV.

Sustainable profitability requires a shift from manpower-driven production to productivity-driven production.

Man-to-Machine Ratio indicates the number of operators deployed per machine on a production line. A high MMR usually signals overstaffing, poor line balancing, or inefficient work methods.

| Section | Acceptable MMR |

|---|---|

| Sewing | 1.0 – 1.2 |

| Cutting | 0.6 – 0.8 |

| Finishing | 0.8 – 1.0 |

⚠️ Many factories operate sewing lines at MMR 1.30–1.50, increasing labour cost per piece by 15%–25%.

Conduct operation-wise time studies

Eliminate redundant helpers

Balance lines to remove bottlenecks

Align manpower with style complexity

📌 Lowering MMR without reducing output is the fastest way to reduce labour cost.

In many factories, IE teams focus on target setting, not cost optimisation. Without accurate SMV and capacity planning, CMV becomes unreliable.

Accurate SMV calculation by operation

Line balancing before production starts

Motion economy and layout redesign

Style feasibility analysis before order confirmation

🎯 Strong IE practices directly reduce manpower requirement and improve efficiency.

CMV measures labour cost per available production minute and is the most accurate indicator of conversion cost efficiency.

CMV=Total Labour CostTotal Available Minutes

Lower CMV = Higher margin.

Excess indirect labour

High absenteeism

Overtime dependency

Frequent style changeovers

Poor capacity utilisation

📉 Factories often quote CM to buyers without knowing their actual CMV, leading to under-pricing.

Indirect labour (supervisors, helpers, quality checkers, mechanics) often accounts for 20%–30% of total labour cost.

Supervisor span-of-control review

Helper-to-operator ratio assessment

Shift-wise manpower alignment

Productivity-linked incentive structures

🧮 Reducing indirect labour improves CMV without affecting production volume.

Strategic investment in semi-automatic machines reduces reliance on manual labour:

Button attach

Pocket setter

Auto trimming

Bar-tack & programmable machines

⚙️ Machine justification should be based on CMV reduction, not just output speed.

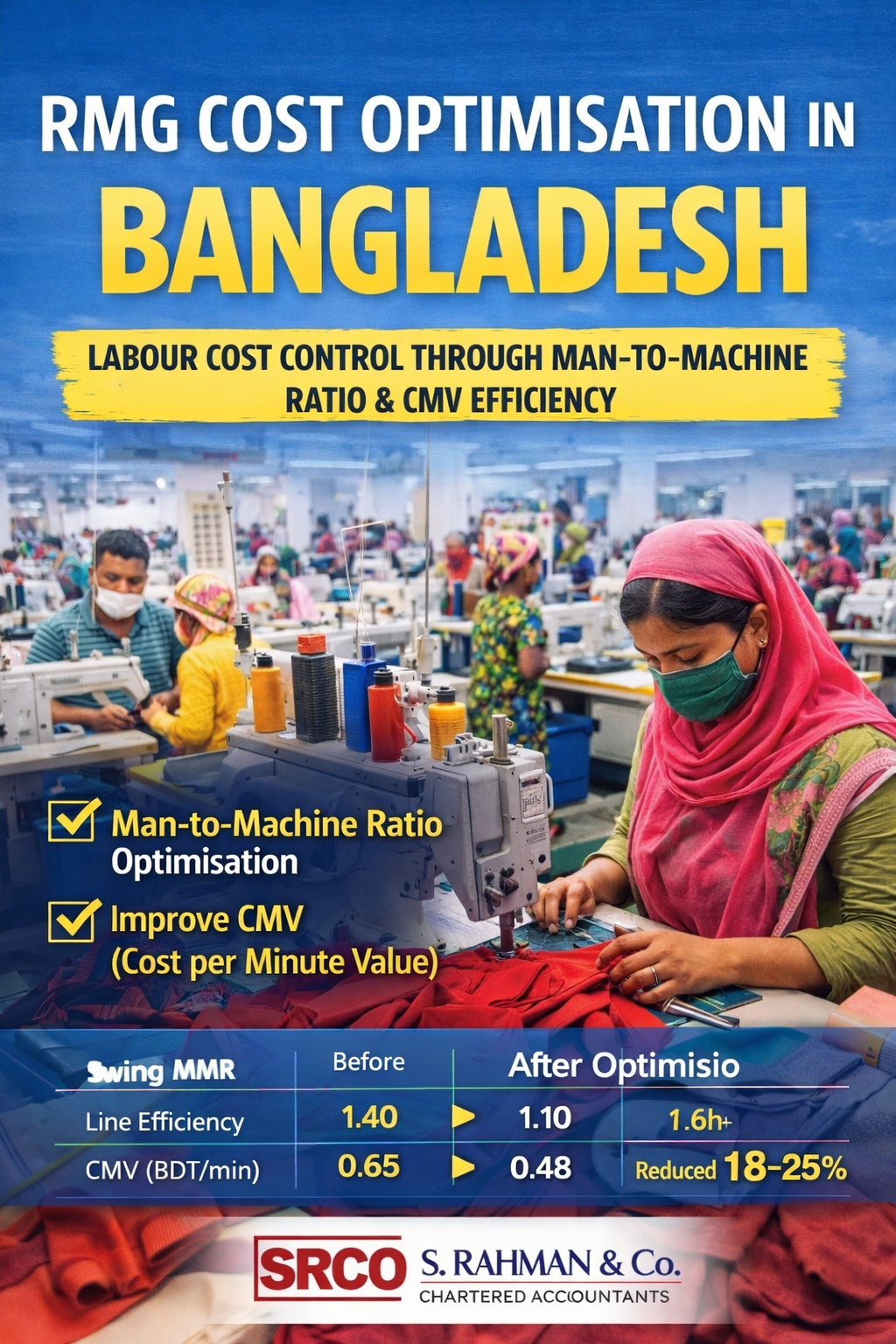

| Area | Before | After Optimisation |

|---|---|---|

| Sewing MMR | 1.40 | 1.10 |

| Line Efficiency | 45% | 60%+ |

| CMV (BDT/min) | 0.65 | 0.48 |

| Labour Cost per Piece | High | ↓ 18–25% |

📊 These savings directly increase net contribution margin.

Buyers are continuously reducing CM

Labour cost is structurally rising

Competing countries are more productive

Compliance costs are non-negotiable

🔑 Only factories that optimise labour scientifically will remain competitive.

A structured labour cost optimisation program includes:

Manpower rationalisation studies

CMV benchmarking & buyer alignment

IE capability strengthening

Profitability analysis by style & buyer

Labour cost optimisation is not cost cutting—it is operational discipline.

RMG profitability in Bangladesh will no longer be driven by volume alone. Man-to-Machine Ratio optimisation and CMV efficiency provide factories with a practical, measurable, and sustainable path to maximise profit while maintaining quality and compliance.

Factories that act now will gain a structural advantage in an increasingly competitive global apparel market.

Blogs